Pipe Connections

Screwed female inlet and outlet connections. outlet connection is one size larger than inlet connection. Threaded connections are Rp parallel to BS EN 10226-1. NPT connections are available upon request.

Testing

All valves are shell and seat tested (to confirm set pressure) before leaving the factory and all valves are supplied pre-set with a tamper proof seal. Pressure Test Certificate and Letters of Conformity available on request.

Product Extras

- Available with Viton seat design

- Pressure setting locked and sealed

- Drain plug fitted on DN32 and above allows fitting of a pressure gauge

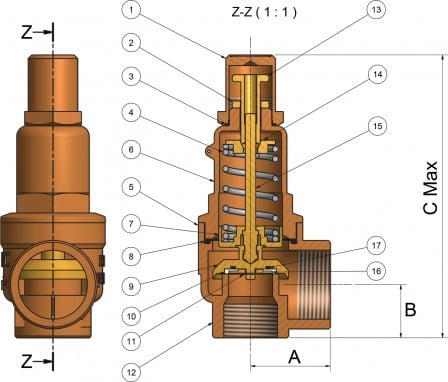

Dimensions & Weights

| SIZE DN |

Rp BSP Inlet |

Rp BSP Outlet |

A (mm) |

B (mm) |

C (mm) |

Weight (Kg) |

|---|---|---|---|---|---|---|

| 15 | 1/2″ | 3/4″ | 33 | 20 | 123 | 0.70 |

| 20 | 3/4″ | 1″ | 39 | 24 | 136 | 0.93 |

| 25 | 1″ | 1 1/4″ | 45 | 30 | 155 | 1.42 |

| 32 | 1 1/4″ | 1 1/2″ | 54 | 36 | 201 | 2.50 |

| 40 | 1 1/2″ | 2″ | 64 | 41 | 236 | 4.63 |

| 50 | 2″ | 2 1/2″ | 76 | 47 | 267 | 7.00 |

| 65 | 2 1/2″ | 3″ | 90 | 60 | 330 | 12.50 |

Materials

| Ref No | Name of Part | Material |

|---|---|---|

| 1 | Leak Proof Dome | Bronze, BS EN 1982 CC491K |

| 2 | Locknut | Brass, BS EN 12164 CW609N |

| 3 | Dome ‘O’ Ring | Viton |

| 4 | Spring | Chrome Vandium Alloy Steel, BS 2803 735 A50 HS (Stainless Steel, BS 2056 302S26 Opt) |

| 5 | Label | Yellow kapton |

| 6 | Spring Cover | Bronze, BS EN 1982 CC491K |

| 7 | Piston | Brass, BS EN 12164 CW609N |

| 8 | Cover Seal | Viton |

| 9 | Seat Seal Holder | Bronze, BS EN 1982 CC491K / Brass BS EN 12164 CW602N (DZR) |

| 10 | Seat Seal | PTFE (Viton Opt) |

| 11 | Starlock Washer | Stainless Steel |

| 12 | Body | Bronze, BS EN 1982 CC491K |

| 13 | Adjusting Screw | Brass, BS EN 12164 CW609N |

| 14 | Spring Plate | Brass, BS EN 12164 CW609N |

| 15 | Spindle | Brass, BS EN 12164 CW721R |

| 16 | Seat Seal Retaining Plate | Bronze, BS EN 1982 CC491K / Brass BS EN 12164 CW602N (DZR) |

| 17 | O-Ring | Viton |