Pipe Connections

Threaded male inlet connection R (BSPT) to BS EN 10226-2 Threaded female outlet connections Rp (BSP) to BS EN 10226-1. Note: The inlet and outlet connections are equal in size and are one size larger than the bore size. The inlet is a male thread, the larger size is to allow for the stainless steel inlet insert.

Testing

All valves are shell and seat tested (to confirm set pressure) before leaving the factory and all valves are supplied pre-set with a tamper proof seal. Pressure Test Certificate and Letters of Conformity available on request.

Product Extras

- Available with Viton seat design

- Padlock available (complies with M&E3)

- Pressure setting locked and sealed

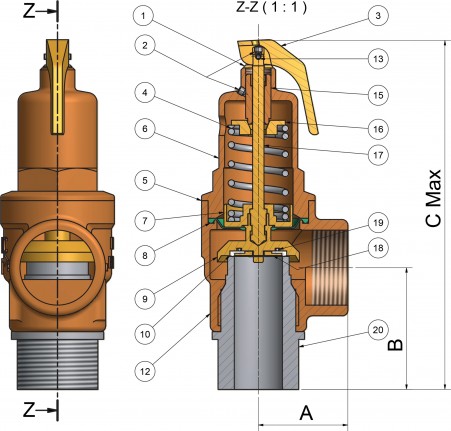

Dimensions & Weights

| SIZE DN |

R BSPT Inlet |

Rp BSP Outlet |

A (mm) |

B (mm) |

C (mm) |

|---|---|---|---|---|---|

| 15 | 3/4″ | 3/4″ | 34 | 46 | 141 |

| 20 | 1″ | 1″ | 39 | 54 | 159 |

| 25 | 1 1/4″ | 1 1/4″ | 46 | 63 | 183 |

| 32 | 1 1/2″ | 1 1/2″ | 54 | 68 | 228 |

| 40 | 2″ | 2″ | 64 | 81 | 271 |

| 50 | 2 1/2″ | 2 1/2″ | 76 | 95 | 315 |

| 65 | 3″ | 3″ | 90 | 110 | 380 |

Materials

| Ref No | Name of Part | Material |

|---|---|---|

| 1 | Thrust Washer | Brass, BS EN 12164 CW609N |

| 2 | Grubscrew | Steel |

| 3 | Test Lever | Brass, BS EN 1982 CC754S |

| 4 | Spring | Chrome Vandium Alloy Steel, BS 2803 735 A50 HS (Stainless Steel, BS 2056 302S26 Opt) |

| 5 | Label | Yellow kapton |

| 6 | Spring Cover | Bronze, BS EN 1982 CC491K |

| 7 | Piston | Brass, BS EN 12164 CW609N |

| 8 | Diaphragm | Silicon Rubber |

| 9 | Seat Seal Holder | Bronze, BS EN 1982 CC491K / Brass BS EN 12164 CW602N (DZR) |

| 10 | Seat Seal | PTFE (Viton Opt) |

| 11 | Starlock Washer | Stainless Steel |

| 12 | Body | Bronze, BS EN 1982 CC491K |

| 13 | Lever Pin | Steel |

| 14 | Lead Seal | Lead |

| 15 | Adjusting Screw | Brass, BS EN 12164 CW609N |

| 16 | Spring Plate | Brass, BS EN 12164 CW609N |

| 17 | Spindle | Brass, BS EN 12164 CW721R |

| 18 | Seat Seal Retaining Plate | Bronze, BS EN 1982 CC491K / Brass BS EN 12164 CW602N (DZR) |

| 19 | O-Ring | Viton |

| 20 | Seat Adaptor | Stainless Steel, BS 970 316S11 |